Yoga pants leggings have gained immense popularity in recent years, becoming a staple in active wear collections worldwide. As the demand for yoga pants leggings rises, the yoga pants leggings manufacturer industry faces challenges in maintaining product quality and addressing customer concerns regarding color deviation and seamless clothing. This article delves into the crucial aspects of color deviation and seamless construction in the yoga pants leggings manufacturing process, and how manufacturers can ensure top-notch products that satisfy both customer preferences and comfort.

1) What is Color Deviation?

Color deviation refers to the variance in color shades between different batches of yoga pants leggings. It can occur due to various factors, including dye lot variations, inconsistent dyeing processes, and variations in fabric properties.

2) Factors Influencing Color Deviation

Several factors contribute to color deviation, such as dyeing temperature, dye concentration, dyeing time, and fabric type. Additionally, environmental factors like humidity and pH levels can also impact color consistency.

3) Impact on Customer Satisfaction

Color deviation can lead to dissatisfied customers, affecting brand reputation and customer loyalty. Customers expect consistency in the product color, especially when they wish to repurchase their favorite yoga pants leggings.

1) Color Matching Techniques

Employing advanced color-matching techniques and spectrophotometers can help manufacturers achieve consistent color across different batches. Regular testing and adjustments during the dyeing process are essential.

2) Precision in Dyeing Process

Maintaining strict quality control during the dyeing process minimizes color deviation. Automated dyeing machines and experienced technicians play a crucial role in achieving precise colors.

3) Importance of Fabric Selection

Choosing high-quality fabrics with uniform properties helps reduce color deviation. Fabric suppliers should adhere to industry standards to ensure consistent results.

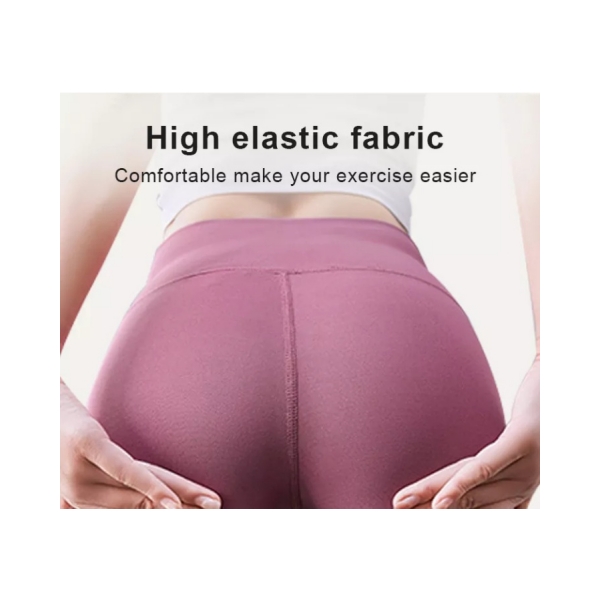

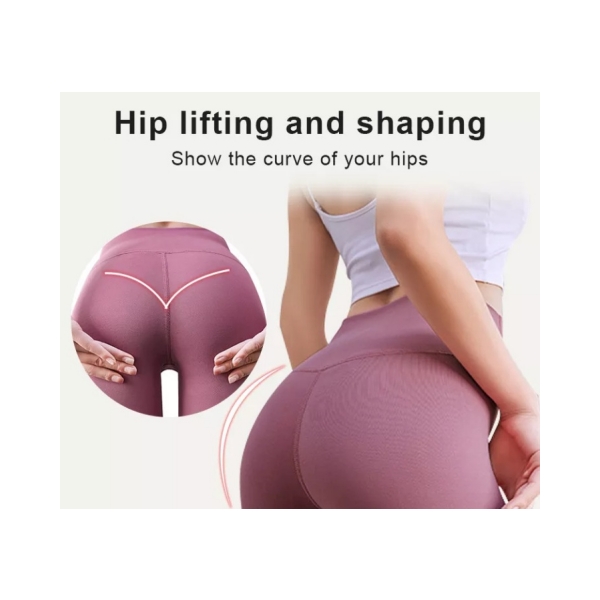

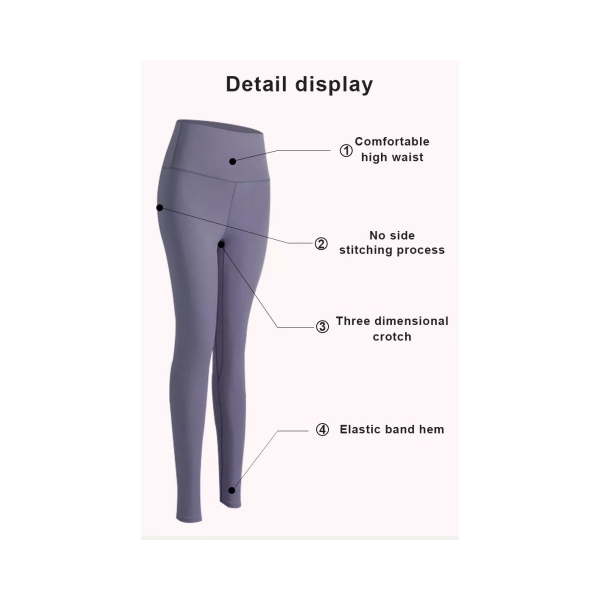

1) Benefits of Seamless Construction

Seamless yoga pants leggings offer enhanced comfort and flexibility, as they eliminate uncomfortable seams that may cause chafing during workouts. The absence of seams also provides a sleek and flattering look.

2) Challenges in Seamless Production

Producing seamless yoga pants leggings requires specialized machinery and skilled operators. Ensuring a consistent fit and minimizing waste are common challenges faced by manufacturers.

3) Innovations in Seamless Technology

Advancements in technology have led to the development of innovative seamless knitting techniques, enabling manufacturers to create unique patterns and designs in seamless yoga pants leggings.

1) Seamless Yoga Pants Leggings Fit Issues

Ensuring a perfect fit for customers of all body types can be challenging. Manufacturers must invest in research and development to create seamless yoga pants leggings that offer a comfortable fit to a wide range of customers.

2) Color Consistency and Brand Reputation

Color deviation can directly impact a brand's reputation. Regular quality checks and maintaining color consistency can foster trust and loyalty among customers.

3) Customer Support and Feedback Loops

Providing excellent customer support and actively seeking customer feedback can help identify and address any issues related to color deviation or seamless construction promptly.

Creating your line of private label gym leggings is a streamlined process designed to bring your vision to life with ease and efficiency. Here are the key steps involved:

1) Conceptualization and Design

At the onset of the process, our expert design team collaborates with you to understand your brand, target market, and design preferences. We assist you in refining your ideas, incorporating the latest trends, and tailoring the leggings to align perfectly with your brand identity.

2) Fabric Selection

We offer an extensive range of premium fabrics that cater to various workout intensities and preferences. Our team guides you in choosing the ideal fabric composition to ensure comfort, breath-ability, and performance.

3) Sample Production and Approval

Once the designs and fabric are finalized, we create sample gym leggings for your evaluation. You can assess the fit, feel, and overall aesthetics to make any necessary adjustments before proceeding to full-scale production.

4) Production and Quality Control

With your approval, we initiate production while maintaining strict quality control measures throughout the manufacturing process. Our team ensures that each pair of gym leggings meets the highest industry standards before leaving our facility.

5) Branding and Packaging

Incorporate your logo and branding elements on the gym leggings to elevate your brand visibility. Our custom packaging options add a final touch of professionalism, making the unboxing experience as remarkable as the product itself.

1) Fusion of Style and Functionality

Manufacturers should stay updated with the latest fashion trends and incorporate them into their yoga pants leggings designs while ensuring comfort and functionality.

2) Customization Options for Customers

Offering customization options allows customers to personalize their yoga pants leggings, enhancing their shopping experience and brand loyalty.

3) Adapting to Athleisure Fashion

Capitalizing on the athleisure trend can expand the customer base for yoga pants leggings and increase demand for fashionable active wear.

1) Seam Strength and Integrity

Strong seams are essential for yoga pants leggings to withstand intense physical activities. Manufacturers must prioritize seam strength during production.

2) Pilling and Abrasion Resistance

Using high-quality fabrics and employing anti-pilling treatments ensures yoga pants leggings maintain their appearance and functionality over time.

3) Balancing Stretch and Recovery

Achieving the right balance between stretch and recovery in yoga pants leggings fabric ensures optimal comfort and shape retention during wear.

1) Technological Advancements

Continued technological advancements will drive innovation in the yoga pants leggings manufacturing process, enabling the creation of cutting-edge products.

2) Virtual Try On and Fit Accuracy

Virtual try on and fit prediction technologies will enhance the online shopping experience, reducing returns and increasing customer satisfaction.

3) Sustainable and Smart Fabrics

The industry will witness a shift towards more sustainable and smart fabrics, catering to Eco-conscious consumers seeking high-performance active wear.

Q: How can manufacturers minimize color deviation in yoga pants leggings?

A: Manufacturers can minimize color deviation through advanced color-matching techniques, precise dyeing processes, and careful fabric selection.

Q: Are seamless yoga pants leggings more comfortable than seamed ones?

A: Yes, seamless yoga pants leggings offer enhanced comfort and flexibility due to the absence of uncomfortable seams.

Q: How can manufacturers make yoga pants leggings more sustainable?

A: Manufacturers can adopt eco-friendly dyeing practices, use recycled fabrics, and implement strategies to reduce textile waste.

Q: Can customers customize their yoga pants leggings?

A: Yes, offering customization options allows customers to personalize their yoga pants leggings according to their preferences.

Q: What does the future hold for the yoga pants leggings industry?

A: The future of the industry lies in technological advancements, virtual try on, sustainable fabrics, and a fusion of style and functionality.

11. Conclusion

The yoga pants leggings manufacturer industry faces exciting challenges and opportunities. Addressing color deviation and ensuring seamless construction are crucial for delivering high-quality products that meet customer expectations. Embracing sustainability, incorporating fashion trends, and exploring technological advancements will shape the industry's future, providing consumers with comfortable, stylish, and environmentally responsible yoga pants leggings. Elevate your brand and captivate your fitness-oriented audience with our private label gym leggings.

By leveraging the power of customization, premium quality, and exceptional service, you can create a unique collection that resonates with your customers, fostering loyalty and brand recognition. Partner with us, and let our expertise and dedication to excellence take your fitness apparel business to new heights. Empower your brand with private label gym leggings that truly stand out in the competitive fitness market.